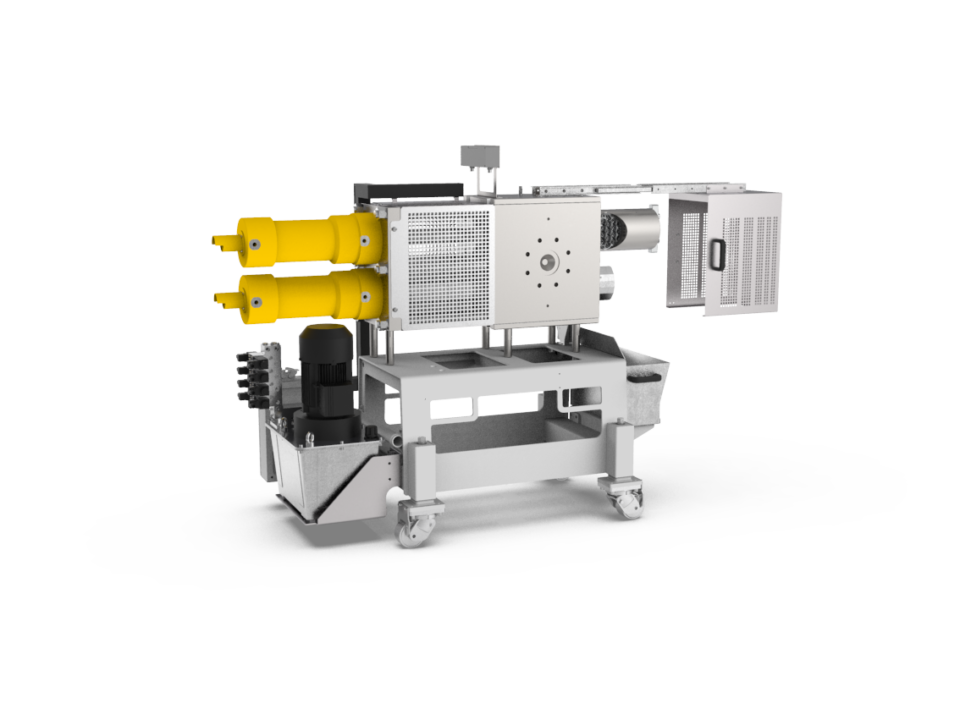

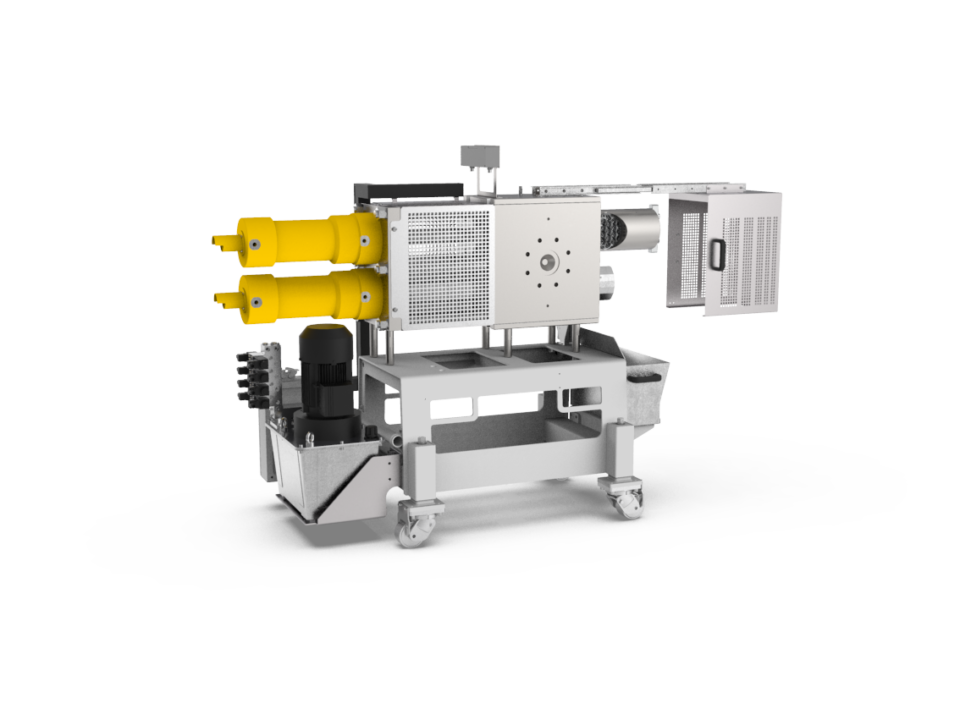

Two screen carrier pistons built in heated filter housing are fed by partial melt channels with contaminated melt.

In case of required screen change, one of the two screen carrier pistons is moved out of the housing. The screen can now be changed and then the screen carrier piston is moved back into the housing. During screen change, the entire melt stream is directed through in housing remaining screen.

Afterwards, the screen in second piston is changed in the same way. The hydraulics for moving the screen carrier pistons can be operated either manually or automatically.

For CMF-ECO version the retrofit kit for back flush function is not applicable.

| BritAS Filter | Screen diameter [mm] | Screen diameter [in] | Screen area [cm²] | Screen area [sqin] | Output [kg/h] | Output [lbs/h] |

| CMF-2/030 ECO | 30 | 1.2 | 2 x 7 | 2 x 1.1 | 15 – 30 | 33 – 66 |

| CMF-2/046 ECO | 46 | 1.8 | 2 x 17 | 2 x 2.6 | 30 – 70 | 66 – 154 |

| CMF-2/058 ECO | 58,3 | 2.3 | 2 x 27 | 2 x 4.0 | 50 – 100 | 110 – 220 |

| CMF-2/076 ECO | 76,3 | 3.0 | 2 x 45 | 2 x 7.0 | 80 – 195 | 176 – 430 |

| CMF-2/096 ECO | 96,3 | 3.8 | 2 x 72 | 2 x 11.2 | 130 – 290 | 286 – 639 |

| CMF-2/116 ECO | 116,3 | 4.6 | 2 x 106 | 2 x 16.4 | 190 – 430 | 418 – 948 |

| CMF-2/125 ECO | 125 | 4.9 | 2 x 122 | 2 x 18.9 | 220 – 490 | 485 – 1080 |

| CMF-2/148 ECO | 148,3 | 5.8 | 2 x 172 | 2 x 26.7 | 310 – 690 | 683 – 1521 |

| CMF-2/176 ECO | 176,3 | 6.9 | 2 x 244 | 2 x 37.8 | 430 – 980 | 948 – 2161 |

| CMF-2/200 ECO | 200 | 7.9 | 2 x 314 | 2 x 48.7 | 560 – 1260 | 1235 – 2778 |

| CMF-2/230 ECO | 230,3 | 9.1 | 2 x 417 | 2 x 64.6 | 750 – 1670 | 1653 – 3682 |

| CMF-2/250 ECO | 250 | 9.8 | 2 x 491 | 2 x 76.1 | 880 – 1960 | 1940 – 4321 |

| CMF-2/300 ECO | 300 | 11.8 | 2 x 707 | 2 x 109.6 | 1270 – 2830 | 2800 – 6239 |

| CMF-2/340 ECO | 340 | 13.4 | 2 x 908 | 2 x 140.7 | 1630 – 3600 | 3594 – 7937 |

| CMF-2/400 ECO | 400 | 15.7 | 2 x 1257 | 2 x 194.8 | 2260 – 5030 | 4982 – 11090 |

| CMF-2/058 | 58,3 | 2.3 | 2 x 27 | 2 x 4.0 | 50 – 100 | 110 – 220 |

| CMF-2/076 | 76,3 | 3.0 | 2 x 45 | 2 x 7.0 | 80 – 195 | 176 – 430 |

| CMF-2/096 | 96,3 | 3.8 | 2 x 72 | 2 x 11.2 | 130 – 290 | 286 – 639 |

| CMF-2/116 | 116,3 | 4.6 | 2 x 106 | 2 x 16.4 | 190 – 430 | 418 – 948 |

| CMF-2/125 | 125 | 4.9 | 2 x 122 | 2 x 18.9 | 220 – 490 | 485 – 1080 |

| CMF-2/148 | 148,3 | 5.8 | 2 x 172 | 2 x 26.7 | 310 – 690 | 683 – 1521 |

| CMF-2/176 | 176,3 | 6.9 | 2 x 244 | 2 x 37.8 | 430 – 980 | 948 – 2161 |

| CMF-2/200 | 200 | 7.9 | 2 x 314 | 2 x 48.7 | 560 – 1260 | 1235 – 2775 |

| CMF-2/230 | 230,3 | 9.1 | 2 x 417 | 2 x 64.6 | 750 – 1670 | 1653 – 3682 |

| CMF-2/250 | 250 | 9.8 | 2 x 491 | 2 x 76.1 | 880 – 1960 | 1940 – 4321 |

| CMF-2/300 | 300 | 11.8 | 2 x 707 | 2 x 109.6 | 1270 – 2830 | 2800 – 6239 |

| CMF-2/340 | 340 | 13.4 | 2 x 908 | 2 x 140.7 | 1630 – 3600 | 3594 – 7937 |

| CMF-2/400 | 400 | 15.7 | 2 x 1257 | 2 x 194.8 | 2260 – 5030 | 4982 – 11090 |

The throughputs are essentially influenced by material, viscosity, filter fineness and degree of contamination.