BritAS Highlights at K 2022, Hall 9,

Booth B20:- Trade fair premiere: First-time presentation of the Automatic Belt Melt Filter ABMF-PET-C at the exhibition stand

- Innovation: Continuous Piston Screen Changer with backflush function CMF-BF as second system at K

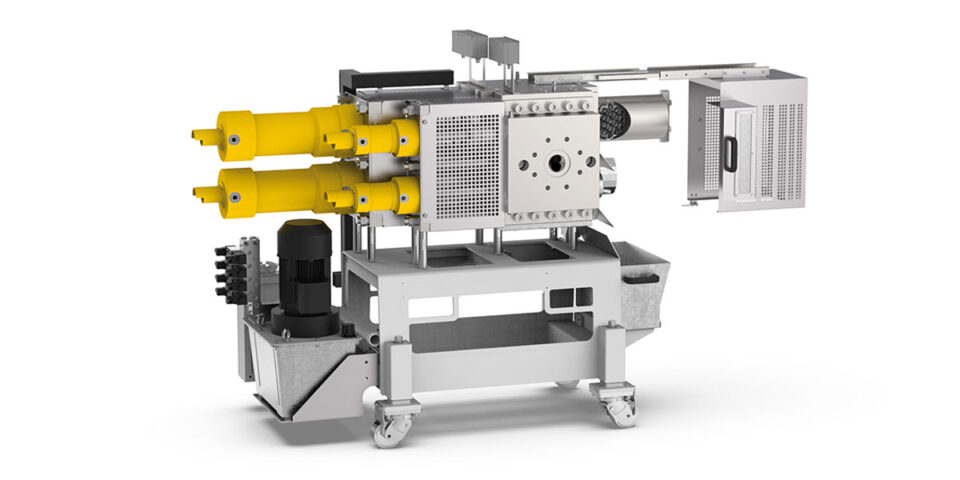

At this year’s K, BritAS will be presenting the ABMF PET-C to the public for the first time. The melt filter for contaminated PET waste is characterised by a wealth of advantages. Visitors to the booth will also be able to get an idea of the innovative CMF-BF Continuous Piston Screen Changer with backflush function.

Consistently high re-granulate quality through fully automatic melt filtration in double-cavity technology – this is what the ABMF-PET-C Automatic Belt Melt Filter stands for. BritAS will be presenting it to the public for the first time at K 2022.

Premiere: ABMF PET-C Continuous – Innovation Melt Filter in Double-Cavity Technology

The ABMF-PET-C uses proven BritAS basic technology and is equipped with special features and technically optimised. “The melt filter is particularly suitable for underwater or strand pelletising. Essential for our customers is the high PET regranulate quality at low operating costs. Filtration fineness down to 20 µm and the low melt loss <1.0 % distinguish the ABMF-PET-C,” explain Thomas Lehner CSO BritAS Recycling-Anlagen and Heiko Henss, CEO BritAS Recycling-Anlagen.

Fully automatic filtration of contaminated post-consumer PET plastic waste

In order to effectively and efficiently filter contaminants from plastic waste, a clean screen belt is automatically inserted into the BritAS filter without stopping production each time the filter is changed. Up to three screen belts can be used at the same time, which allows different filter fineness to be precisely matched. “As a result, the quality of the re-granulate remains consistently high and the dirt is discharged from the machine with very little melt loss.”

In combination, the filter mechanism and control system provide fully automatic, practical operation in double-cavity mode, which requires no intermediate storage of melt. The extruder continues to run during the screen feed, ensuring process reliability.

Applicable for post-consumer plastic waste with a focus on PET as well as PET-like materials, low-viscosity plastics such as PA, the BritAS innovation also impresses with its practical operation. “The ABMF-PET-C is the perfect solution especially for heavy contamination,” say Lehner and Henss.

High throughput rates, high output, low operating costs

“In addition to the automatic operation of the double-cavity filter with high plastic throughput, the use of screen belts with Dutch weave ensures high output. Furthermore, the optimised inner workings of the ABMF-PET-C and the revised heating system keep the operating costs of the melt filter low,” explains DI Dr. Friedrich Kastner, Chairman / Managing Partner BritAS Recycling-Anlagen GmbH. The ABMF-PET-C is available to customers with a filter area of 1,140 cm2 to 3,200 cm2 and a maximum output of 1,030 kg/h to 4,800 kg/h.

Innovation: CMF-BF Continuous Piston Screen Changer with Backflush Function

At the K booth, BritAS will also be presenting the CMF-BF continuous piston screen changer with backflush function.

The CMF-BF is able to clean the filters automatically. There are two backflush pistons in an attachment module which enable an automatic backflush process. When a filter change is required, one of the two backflush pistons is first moved into the backflush position.

This interrupts the melt flow of the corresponding filter. A small melt flow of the already cleaned material is branched off and directed backwards through the filter to be cleaned and discharged to the outside. This process is then repeated automatically for the second filter.

Ideal for less contaminated industrial & production plastic waste

The CMF series consists of four filter types – discontinuous and continuous variants, covering all customer requirements. BritAS piston screen changers are designed for the recycling of plastic waste that is less contaminated. Piston screen changers are primarily used in the post-industrial and post-production sectors, as well as for virgin material. Depending on the required throughputs and different operating modes, customers choose between the discontinuous – primarily with one bolt – or the continuous – with two bolts – version.

Further companies of the NGA Group at the K 2022

COLLIN Lab & Pilot Solutions GmbH in Hall 9, Booth B16, live operation – COLLIN Blown Film Line PILOT LINE BL 600 P, TEACH LINE Extruder, Compounder, Chill Roll, MEDICAL LINE Tube Line, LAB LINE Press and Roll Mill

COMELT is member of the NGA Next Generation Analytics Group, which is represented by the following other companies at the K:

NGA Plastic Technology Pvt. Ltd. – Hall 10, Booth H18, live operation – EASY LINE Blown Film Line, Chill Roll, Compounder, Pressure Filter Test, Extruder & Roll Mill